Facilities

Inami Plant

At the Inami factory we primarily manufacture buckets and fuel tanks-essential components for hydraulic excavator-but at the customers’ request, we produce small order items in addition to a wide variety of other products in a timely manner.

We fully understand that at times an order must be fulfilled within a minimum amount of time, and in order to provide high quality products within a limited time frame, we have established a state of the art manufacturing line that can be modified accordingly to meet the individual needs of our customers.To this end we’ve developed our own robotic assemble & welding system, and have M/C and press-machines at our disposal.Not only that but if the customer desires, our manufacturing line that doesn’t compromise quality.

Welding robots

We operate a total of 20 welding robots, which enable us to deliver products of consistently high quality irrespective of changes in production quantities or model type. Each day we work to reach our goal of 100% automated production.

Five-face machining center

This five-face machining center is used to fabricate blades, cab frames, and other construction machinery attachments with relatively large dimensions, including booms, arms, and similar components. We gladly accept orders even for single items.

Painting equipment

Each of our production lines has its own paint equipment. We use solvent-borne paint for all production parts, to which primer coats are applied by robots and finish coats of urethane paint are applied by hand. For smaller products and prototypes, we have a booth that is suitable for a wide variety of paint applications.

Tsuchiyama Plant

The Tsuchiyama plant traces its origin to the manufacture of megalithic components to be used in large sea vessels. Since then our operations have expanded to include the manufacture of parts for nuclear and thermal power plants, diesel engine parts and valuable components to be used in construction machines. The Tsuchiyama facility boasts a variety of manufacturing equipment (e.g.large cranes, press-machines, 3-D inspection equipment, cutting machines, and shot-blast machines) and has established its presence in the made-to-order business.

Map

Horizontal borer

The introduction of numeric-control equipment has enabled us to produce both heavy-duty plate-metal products for industrial equipment and precision sheet-metal parts that satisfy a wide range of requirements for dimensional accuracy.

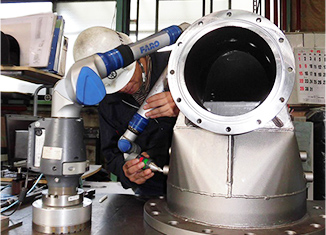

3-D measurement device

3-D measurement is an essential part of the strict quality inspection process we use to guarantee dimensional accuracy of all our products, irrespective of how complex their shape.

List of major equipment

| Name | Maker | Model | Qty. | Specifications |

|---|---|---|---|---|

| Vertical machining center | Okuma | MILLAC852VⅡ | 1 | Table size: 2,200 × 850 mm |

| Vertical machining center | Okuma | MILLAC 761V II | 1 | Axis lengths: X = 1,540, Y = 760, and Z = 660 mm Table size: 1,800 × 720 mm |

| Horizontal machining center | Niigata Machine Techno | BHN-80D | 2 | Table size: 800 × 800 mm 4-side pallet with U-axis |

| Horizontal borer | Toshiba Machine | BTD-110R16 | 1 | Axis lengths: X = 2,000, Y = 1,500, Z = 1,450, and W = 500 mm Table size: 1,800 × 1,600 mm |

| Horizontal borer | Toshiba Machine | BTD-100R12 | 1 | Axis lengths: X = 1,500, Y = 1,200, Z = 700, and W = 350 mm Table size: 1,800 × 1,200 mm |

| Five-face machining center | Mitsubishi Heavy Industries | MVR30 | 1 | Axis lengths: X = 5,200, Y = 3,000, Z = 800, and W = 1,100 mm Column span: 2,550 mm Pallet size: 2,000 × 5,000 |

| Material-handling and welding robot | Yaskawa Electric | MOTOMAN-GP180 | 1 | Max. mass: 150 kg Built-in automatic welder |

| Welding robot | Kobe Steel | A60 | 4 | - |

| Welding robot | Kobe Steel | RONmk2 | 4 | - |

| Welding robot | Kobe Steel | GS | 1 | - |

| Welding robot | Kobe Steel | ceiling mounted MP | 1 | - |

| Welding robot | Kobe Steel | MP | 6 | - |

| Welding robot | Panasonic Welding Systems | TA1800WGH | 4 | - |

| 100-ton hydraulic press | Tsukishima Kikai | HSO-100 | 1 | - |

| 60-ton press brake | Baykal japan | APHS21060 | 1 | Low top table specification for deep bending |

| 200-ton hydraulic press | Osaka Jack | Gantry hydraulic press A-00819 | 1 | Bolster: 2,000 × 1,000 mm |

| 500-ton hydraulic press | Neagari Shibuya | NTN-5000 | 1 | - |

| 500-ton gantry hydraulic press | Kawasaki Hydromechanics | BPR-500 | 1 | - |

| NC roll bender | Kurimoto | MP130 | 1 | Hydraulic pressure: 130-ton 2,000 W Min. bending radius: 340 mm |

| Fuel tank paint line | Nissei Engineering | - | 1 | Length: 56 m Capacity: 300 kg Two booths, one drying oven |

| Painting robot | Asahi Sunac | AF21 | 1 | Max. reach: 1,973 mm Paint gun: EAB90 Pump: PD30 |

| Shearing machine | Aizawatekkousyo | ATS-1325 | 1 | - |

| Sawing machine | Amada | - | 2 | - |

| Shot blast | Sintokogio | - | 1 | 2,000-mm dia. × 2,000-mm height Max. hoist load: 1.5 tons |

| Shot blast | Ascon | 3,000 × 5,000 mm | 1 | - |

| Shot blast | Daichu | LT-1 1,000-mm diameter | 1 | - |

| 3-D inspection equipment | FARO Japan | - | 2 | - |

| 3-D inspection equipment | Keyence | - | 1 | - |

| 3DCAD | - | - | 1 | - |

| 2DCAD | - | - | 4 | - |

| Phosphate pre treatment | Nissay Engineering | - | 1 | 1,750 × 2,700 × 1,725 |